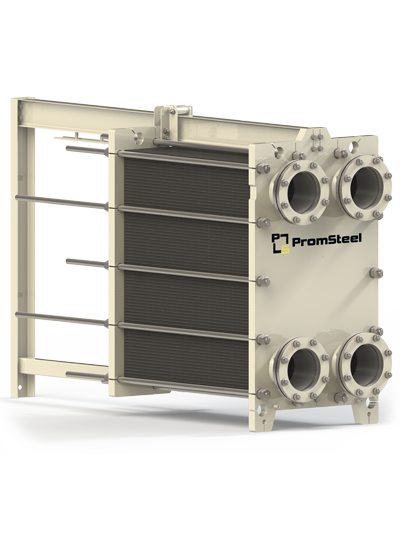

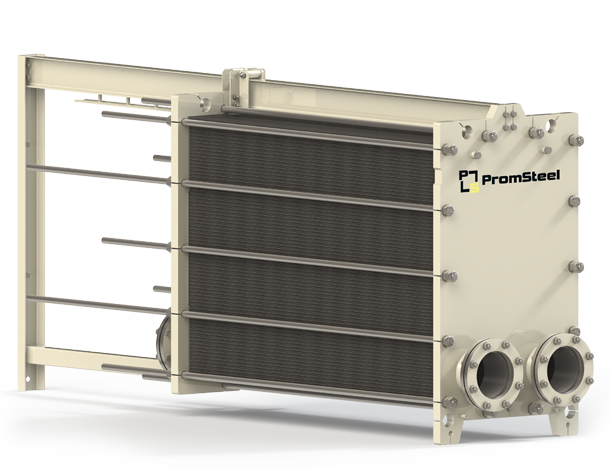

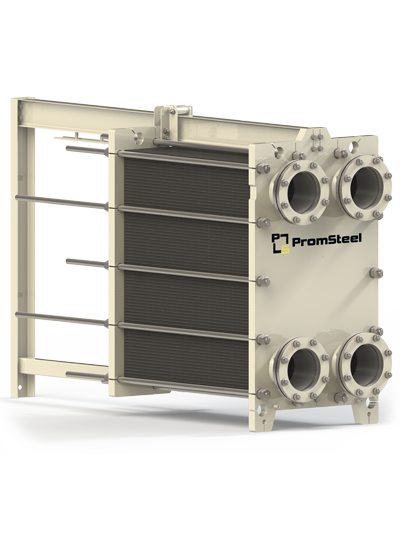

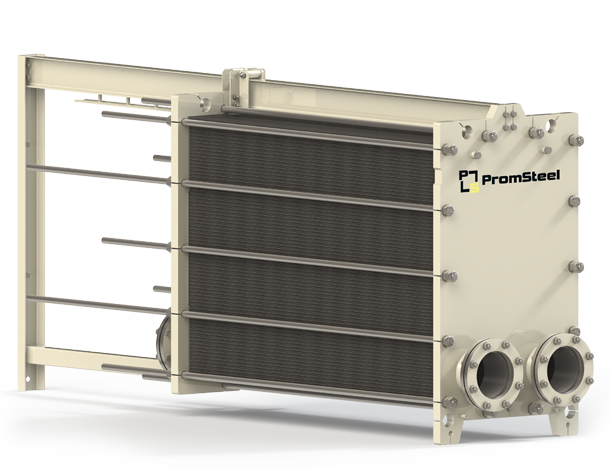

Wide channel heat exchanger

Wide-channel heat exchangers are used at those stages of product processing where the liquid participating in heat exchange has inclusions in the form of particles, fibers, etc. Due to the wide channels, the formation of blockages and blockages is eliminated, which makes this type of heat exchanger effective for working with viscous media and liquids with a high content of mechanical impurities.

Description and design

The heat exchanger consists of a frame, inside of which there is a package of heat exchange plates with gaskets The design of the heat exchanger allows easy access to the heat exchange package for cleaning, maintenance and repair.

- — Frame

- — gaskets

- — plates

- — Fasteners

- — Flanges

SPECIFICATIONS

- Temperature Range

- from -30 to +150 ° С

- Maximum working pressure

- 10 bar

- Heat load

- 50 МW

- Channel width

- from 5 to 16 mm

- Gasket material

- EPDM, NBR, VITON

- Plate material

- AISI 304/AISI 316 Hastelloy С-276/ SMO 254 /Titanium/Nickel 200

Advantages of PromSteel's wide-channel heat exchangers

LOW COST IN COMPARISON WITH tube HEAT EXCHANGERS

POSSIBILITY OF INCREASING / DECREASING THE POWER OF THE APPARATUS

COMPACT DESIGN

Application on viscous media with large inclusions

POSSIBILITY OF DELIVERY IN FOOD PERFORMANCE

DELIVERY WITH DIFFERENT CONNECTION TYPES

butt weld nipples, collars, flanges, threads, etc.

HIGH REPAIRABILITY

CLEANABILITY ON BOTH SIDES (media)

Wide-channel PromSteel's heat exchangers have a minimum number of points of contact of one plate with another, the channels that pass between the plates have a constant cross-section and the maximum gap between the plates is 16 mm

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.