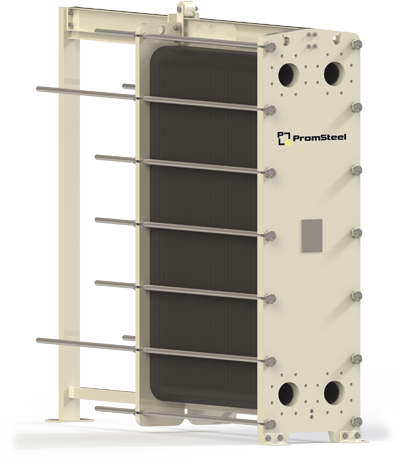

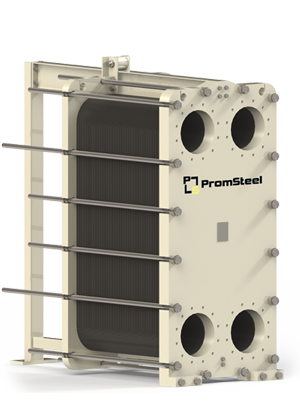

Plate heat exchanger

The gasketed heat exchanger solves many tasks for heating and cooling various media in technological processes.

Gasketed heat exchangers are compact in design, require little installation space and provide efficient heat transfer.

Description and design

The heat exchanger consists of a frame, inside of which there is a pack of heat exchange plates with gaskets. The design of the heat exchanger allows easy access to the heat exchange package for cleaning, maintenance and repair.

- — Frame

- — Gaskets

- — Plates

- — Fasteners

- — Flanges

Specifications

- Temperature Range

- from -30 to +150 ° С

- Max. working pressure

- 25 bar

- Heat load

- 50 МВт

- Standard materials of gaskets

- EPDM, NBR, VITON

- Standard materials of the pack

- AISI 304/AISI 316/ Hastelloy С-276/ SMO 254 /Titanium/Nickel 200

Advantages of PromSteel's gasketed heat exchangers

Low cost compared to tubular heat exchangers

Possibility to increase / decrease the power of the heat exchanger

Can be cleaned on both sides (media)

Compact design

High maintainability

Spare parts are always available in stock

Available with different connection types

butt weld nipples, collars, flanges, threads, milk fittings, etc.

Possibility of supply in food grade

Complete disassembly of the heat exchanger, mechanical or chemical cleaning of the heat exchange surface, replacement of any plate or gasket is possible. You can increase the heat transfer surface by adding the required number of plates.

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.