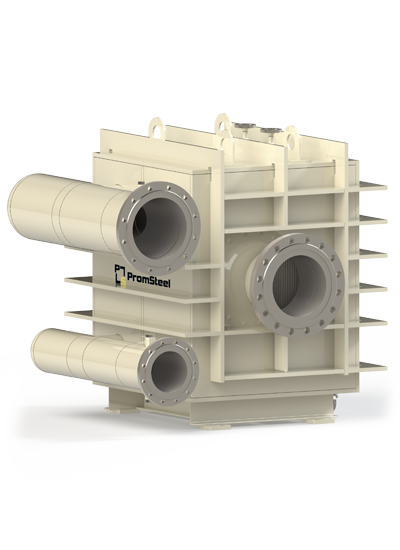

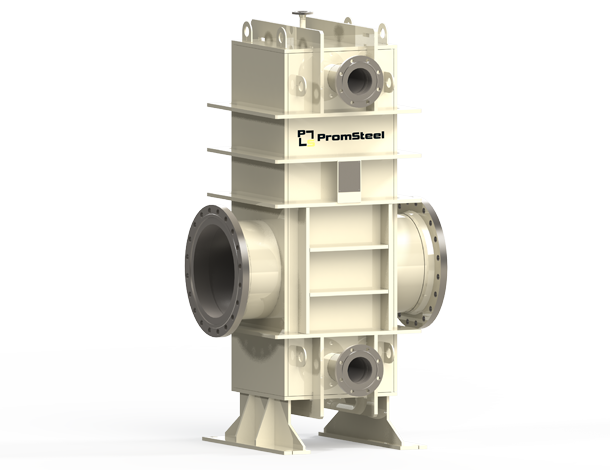

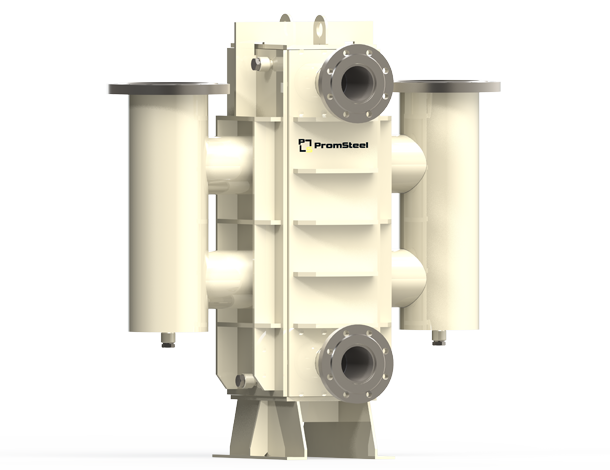

Fully welded heat exchanger

Fully welded heat exchanger these are compact, efficient heat exchangers of increased reliability, which provide a high economic effect. This type of heat exchanger is successfully used for operation with extremely high temperatures and pressures, for highly viscous liquids and media that destroy rubber seals.

Description and design

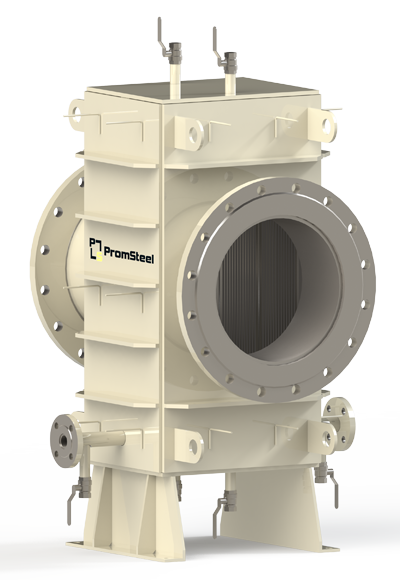

The heat exchanger consists of a fully welded body and a heat exchange package inside.

- — fully welded body

- — heat exchange package

- — flanges

- — paws

SPECIFICATIONS

- Temperature Range

- from -200 to +650 ° С

- Maximum working pressure

- 100 bar

- Heat load

- 250 МW

- Standard of materials

- AISI 304/AISI 316 /Hastelloy С-276/ SMO 254/ Cronifer 1925 hMo /Titanium/Nickel 200

Advantages of PromSteel's fully welded heat exchangers

Lack of stagnant zones

Significantly extends the device's mileage between cleanings

COMPENSATION OF TEMPERATURE EXPANSION

Provided in the design of the device

SIZE AND WEIGHT A FEW TIMES LESS

Compared to shell-and-tube heat exchangers

PRESSURE DIFFERENCE

Can reach 70 bar between cavities

POSITIONING OF FITTINGS

Possible options for the location of the fittings in the device for the existing piping

Extreme temperatures

Operation at temperatures from -200 ° С to + 650 ° С

High pressures

Operation at pressures up to 100 bar

Work in aggressive environments

There are no gaskets in the device

When forming heat exchange packages, unlike foreign-made devices, there is no intersection of welds and welding of elements of different thickness. This significantly increases the reliability of the structure, excludes mutual loosening of welded seams

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.