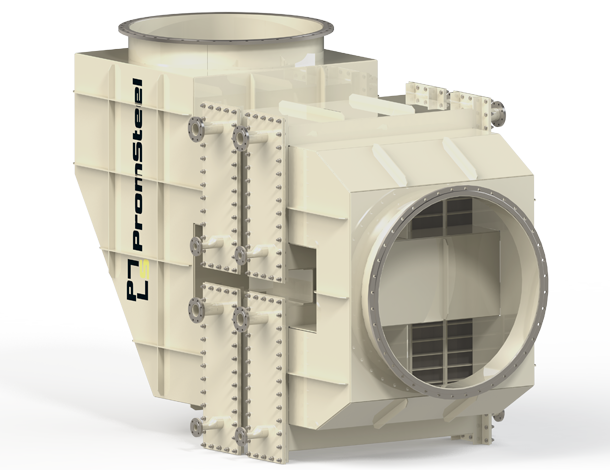

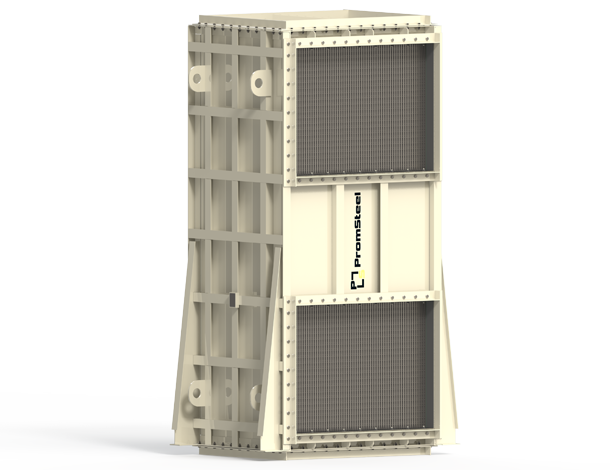

Flue gas heat recovery unit

The waste heat exchanger of flue gases allows a part of the heat of the exhaust flue gases to be returned to the process or used for other needs, which means that it can reduce energy costs or increase productivity. For example, use the heat of flue gases to heat the air supplied to the combustion chamber; for heating heating water, boiler feed water or for heating a feed stream. The purpose of using the device may be to reduce the temperature of flue gases before gas cleaning. This equipment not only solves the problems of heat exchange, but also makes money for its owners..

Description and design

The apparatus consists of a welded body, inside which is located the heat exchange surface. The heat exchange surface can be made of flat sheets or smooth heat exchange tubes. The fittings and supports are designed taking into account the reference to a specific place of operation. The design provides access to the internal devices of the device for cleaning, maintenance and repair.

- — Body

- — Heat exchange package

- — Fittings

Specifications

- Temperature Range

- from -50 to +1150 ° С

- Maximum working pressure

- 100 bar

- Heat load

- 20 МW

- Standard of materials

- structural steels / stainless steels / heat-resistant steels / special alloys

Advantages of PromSteel's flue gas heat recovery units

Operation in a wide range of temperatures and pressures

The design may include compensation for thermal expansion

Calculation and design for a specific task

Site-specific design

The pressure difference between the cavities can be up to 100 bar

Access for mechanical cleaning, revisions, repairs

Reliability and durability

Low payback period

Flue gas heat recovery units manufactured by PromSteel effectively solve heat exchange problems and earn money for their owners.

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.