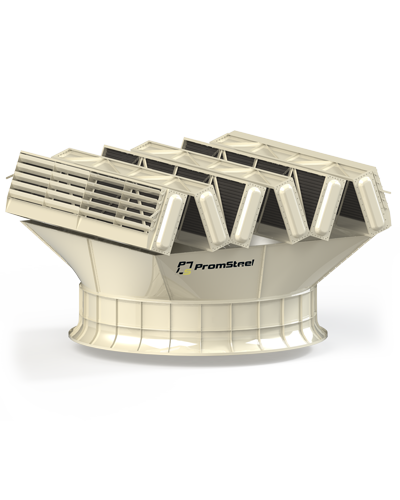

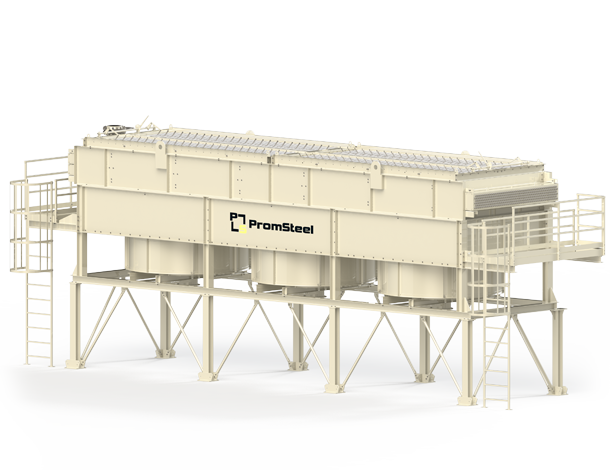

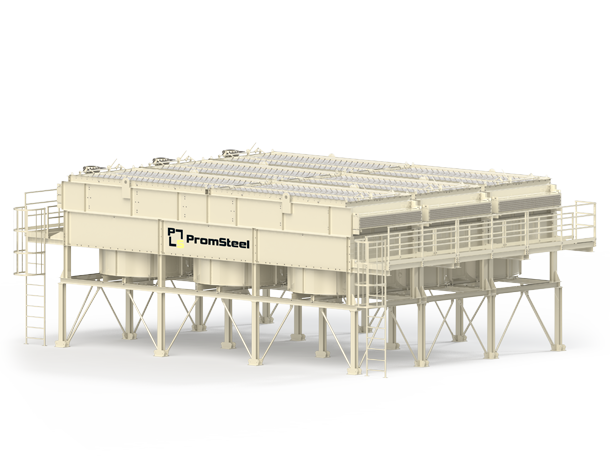

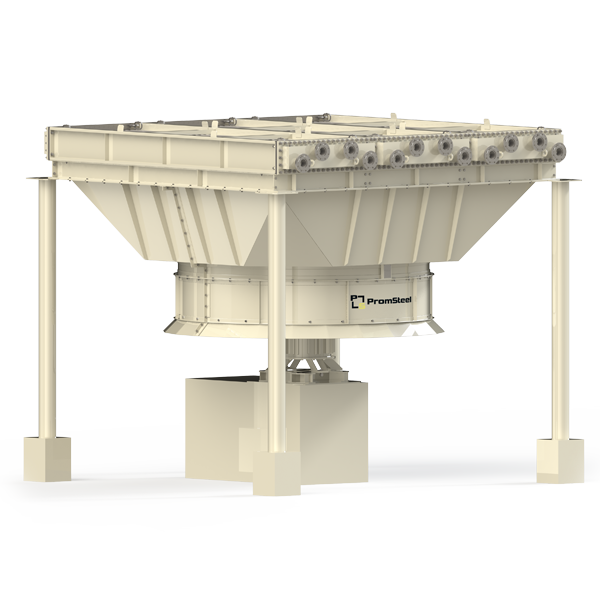

Air cooler

Air coolers are used in industrial plants for cooling liquids and gases, as well as for condensation of vapor-liquid and vapor media in technological processes. In air coolers, atmospheric air is used as a coolant, so they can be classified as surface coolers. Air coolers (often called air coolers or air condensers) are designed to operate over a wide range of pressures and temperatures.

Description and design

The air cooler consists of heat exchange sections with finned tubes, a fan, an electric motor, an air supply channel to the heat exchange sections (fan manifold and diffuser) and metal structures. Additionally, the air cooler can be equipped with blinds, an air humidifier, an air heater, and an air recirculation system. Air coolers are usually divided into horizontal, low-flow, zigzag and delta-shaped. The type is determined according to the location of the heat exchange sections.

- — heat exchange section

- — ventilator

- — electric motor

- — collector

- — diffuser

- — load-bearing metal structure

Specifications

- Max. temperature of the medium to be cooled

- +400 °С

- Nominal pressure

- up to 63 bar

- Finned tube length

- up to 8 m

- Number of sections

- 1-6 pcs

Advantages of PromSteel's air coolers

Cooling capability in the absence of water sources

Increased resistance to corrosion and wear

Longer running time between cleanings

The admixture of water in the cooled product is excluded

Savings on operating costs

Environmental Safety

Extensive adjustment options for precise adherence to operating conditions

Flexible configuration

One of the significant advantages of air coolers is a reduction in operating costs due to the use of air as a heat carrier, environmental safety and high wear resistance.

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.